The post 氧氣截止閥 appeared first on 上海三維閥門制造有限公司.

]]>結構特點

氧氣截止閥除了具有普通閥門的功能外,又有其自身的特點。在制造時采用嚴格的禁油措施,并且所有零件在安裝前均進行嚴格的脫脂處理。所有通徑閥門法蘭端均設有導電螺孔,以防靜電。閥門外露部位有保護措施,防止塵土和油類污染。該類產品的所用材料分兩大類:一類是選用了鑄造硅黃銅為閥體、閥蓋、閥瓣的用材;另一類是選用了優質不銹鋼為閥體、閥蓋、閥瓣的用材。

設計與制造標準

- 設計與制造:GB12235

- 法蘭尺寸:GB9113

- 結構長度:GB12221

- 檢驗與實驗:GB/T13927

主要性能和使用范圍

| 型號 | 公稱壓力 | 殼體試驗壓力Ps(Mpa) | 氣密封試驗 | 適用溫度(℃) | 適用介質 | |

| 水 | 氣 | |||||

| YJ41W-25P YJ41W-40P |

2.5 | 3.8 | 2.5 | 2.5 | 常溫 | 氧氣 |

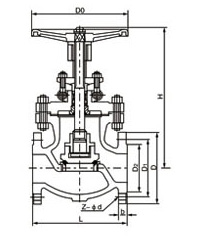

主要外形尺寸

| YJ41W-40P、YJ41W-40R | 重 量 (kg) |

|||||||||||||

| 公稱通徑 DN(mm) |

尺 寸 (mm) | |||||||||||||

| L | D | D1 | D2 | D6 | b | f | fz | z-фd | Dz | i | H | D0 | ||

| 15 | 130 | 95 | 65 | 45 | 40 | 16 | 2 | 4 | 4-ф14 | 82 | 10 | 202 | 100 | 5 |

| 20 | 150 | 105 | 75 | 55 | 51 | 16 | 2 | 4 | 4-ф14 | 95 | 13 | 225 | 100 | 6.5 |

| 25 | 160 | 115 | 85 | 65 | 58 | 16 | 2 | 4 | 4-ф14 | 98 | 15 | 236 | 125 | 7 |

| 32 | 190 | 135 | 100 | 78 | 66 | 18 | 2 | 4 | 4-ф18 | 120 | 28 | 312 | 180 | 13.5 |

| 40 | 200 | 145 | 110 | 85 | 76 | 18 | 3 | 4 | 4-ф18 | 135 | 20 | 328 | 160 | 16 |

| 50 | 230 | 160 | 125 | 100 | 88 | 20 | 3 | 4 | 4-ф18 | 160 | 25 | 450 | 320 | 32 |

| 65 | 290 | 180 | 145 | 120 | 110 | 22 | 3 | 4 | 8-ф18 | 180 | 30 | 530 | 360 | 45 |

| 80 | 310 | 195 | 160 | 135 | 121 | 22 | 3 | 4 | 8-ф18 | 195 | 32 | 560 | 400 | 60 |

| 100 | 350 | 230 | 190 | 160 | 150 | 24 | 3 | 4.5 | 8-ф23 | 230 | 40 | 618 | 450 | 80 |

| 125 | 400 | 270 | 220 | 188 | 176 | 28 | 3 | 4.5 | 8-ф25 | 275 | 42 | 675 | 450 | 105 |

| 150 | 480 | 300 | 250 | 218 | 204 | 30 | 3 | 4.5 | 8-ф25 | 330 | 50 | 743 | 560 | 134 |

| 200 | 600 | 375 | 320 | 282 | 260 | 38 | 3 | 4.5 | 12-ф30 | 405 | 55 | 850 | 640 | 266 |

| 250 | 650 | 445 | 385 | 345 | 313 | 42 | 3 | 4.5 | 12-ф34 | 480 | 88 | 975 | 720 | 491 |

| 300 | 750 | 510 | 450 | 408 | 364 | 46 | 4 | 4.5 | 16-ф34 | 520 | 100 | 1115 | 800 | 705 |

| 400 | 950 | 655 | 585 | 535 | 474 | 58 | 4 | 5 | 16-ф41 | 650 | 140 | 1425 | 900 | 1234 |

The post 氧氣截止閥 appeared first on 上海三維閥門制造有限公司.

]]>The post 美標截止閥 appeared first on 上海三維閥門制造有限公司.

]]>標準

| 設計與制造 Design and Manufacture | 結構長度 Face to face/ End to end | 法蘭尺寸 Flange Dimension | 對焊連接尺寸Butt welding dimension | 壓力-溫度 Pressure Temperature Lating | 試驗-檢驗Inspection and Test |

| ANSI B16.34 BS1873 | ANSI B16.10 | ANSI B16.5 | ANSI B16.25 | ANSI B16.34 | API 598 |

壓力試驗

| 公稱壓力PN(Lb) NominalPressure |

強度試驗 Shell Test |

氣密封試驗 Air Seal Test |

氣密封試驗 Air Seal Test |

|||

| MPa | Lbf/in2 | MPa | Lbf/in2 | MPa | Lbf/in2 | |

| 150 | 3.0 | 430 | 2.2 | 315 | 0.4-0.7 | 60-100 |

| 300 | 7.7 | 1110 | 5.7 | 815 | ||

| 600 | 15.3 | 2220 | 11.3 | 1630 | ||

| 900 | 23.0 | 3330 | 17.0 | 2445 | ||

| 1500 | 38.4 | 5560 | 28.2 | 4080 | ||

| 2500 | 64.0 | 9255 | 47.0 | 6790 | ||

主要零件材料及性能

| 體、蓋 | 閥桿 | 密封面 | 墊片(環) | 填料 | 工作溫度 | 適用介質 |

| WCB | 2Cr13 | 13Cr STL 木體材料 With Body Material 尼龍 Nylon |

增強柔性石墨 13Cr/柔性石墨 Enhanced Flexible Graphite 1Cr13/Flexible Graphite SFB-2 08軟鋼 08 Soft Steal F304 F316 F304L F316L |

柔性石墨 增強柔性石墨 Flexible Graphite Enhanced Flexible Graphite SFB/260 SFP/260 PTFE |

≤425 | 水 蒸汽 油品 Water Steam Petroleum Products |

| WC1 | 38CrMoAl 25Cr2MoV | ≤425 | ||||

| WC6 | ≤540 | |||||

| WC9 | ≤570 | |||||

| C5 C12 | ≤540 | |||||

| CF8 | F304 | ≤200 | 硝酸 醋酸 尿素 Nitric acid Acetic acid |

|||

| CF8M | F316 | |||||

| CF3 | F304L | |||||

| CF3M | F316L |

產品外形尺寸圖

主要尺寸和重量

| DN | 150Lb 凸面法蘭(RF)?主要尺寸Dimensions(mm) | 重量 Weight | ||||||||

| mm | in | L | D | D1 | D2 | b | n-φd | H | D0 | |

| 15 | 1/2 | 108 | 89 | 60.5 | 35 | 11.2 | 4-16 | 241 | 100 | 6.9 |

| 20 | 3/4 | 117 | 98 | 69.9 | 43 | 12.7 | 4-16 | 241 | 100 | 9.8 |

| 25 | 1 | 127 | 108 | 79.2 | 51 | 14.2 | 4-16 | 242 | 125 | 13.5 |

| 32 | 11/4 | 140 | 117 | 89 | 63 | 16 | 4-16 | 280 | 160 | 19.5 |

| 40 | 11/2 | 165 | 127 | 98.6 | 73 | 17.5 | 4-16 | 286 | 160 | 28.5 |

| 50 | 2 | 203 | 152 | 120.7 | 92 | 19 | 4-19 | 368 | 200 | 18 |

| 65 | 21/2 | 216 | 178 | 139.7 | 105 | 22.4 | 4-19 | 387 | 200 | 30 |

| 80 | 3 | 241 | 190 | 152.4 | 127 | 24 | 4-19 | 411 | 250 | 41 |

| 100 | 4 | 292 | 229 | 190.5 | 157 | 24 | 4-19 | 454 | 250 | 64 |

| 125 | 5 | 356 | 254 | 216.0 | 186 | 24 | 8-22.5 | 455 | 350 | 86 |

| 150 | 6 | 406 | 279 | 241.3 | 216 | 25.4 | 8-22.5 | 541 | 350 | 113 |

| 200 | 8 | 495 | 343 | 298.5 | 270 | 28.4 | 8-22.5 | 651 | 450 | 178 |

| 250 | 10 | 622 | 406 | 362.0 | 324 | 30.2 | 12-25.4 | 800 | 450 | 270 |

| 300 | 12 | 698 | 483 | 431.8 | 381 | 32 | 12-25.4 | 1231 | 600 | 350 |

| 350 | 14 | 787 | 533 | 476.3 | 413 | 35 | 12-29 | 1450 | 600 | 460 |

| 400 | 16 | 914 | 597 | 539.8 | 470 | 36.6 | 26-29 | 1645 | 600 | 590 |

| DN | 300Lb 凸面法蘭(RF)?主要尺寸Dimensions

(mm) |

重量 Weight | ||||||||

| 15 | 1/2 | 152 | 95 | 66.5 | 35 | 14.2 | 4-16 | 241 | 140 | 7.7 |

| 20 | 3/4 | 178 | 117 | 82.5 | 43 | 16 | 4-19 | 241 | 140 | 11.3 |

| 25 | 1 | 203 | 123 | 89 | 51 | 17.5 | 4-19 | 283 | 160 | 16.8 |

| 32 | 11/4 | 216 | 133 | 98.5 | 63 | 19 | 4-19 | 320 | 200 | 21.2 |

| 40 | 11/2 | 229 | 155 | 114.3 | 73 | 20.6 | 4-22.5 | 322 | 200 | 32.6 |

| 50 | 2 | 267 | 165 | 127 | 92 | 22.4 | 8-19 | 399 | 200 | 25 |

| 65 | 21/2 | 292 | 190 | 149.4 | 105 | 25.4 | 8-22.5 | 438 | 250 | 30 |

| 80 | 3 | 318 | 210 | 168.1 | 127 | 28.4 | 8-22.5 | 464 | 280 | 35 |

| 100 | 4 | 356 | 254 | 200.2 | 157 | 31.8 | 8-22.5 | 565 | 350 | 56 |

| 125 | 5 | 400 | 279 | 235 | 186 | 35 | 8-22.5 | 614 | 350 | 96 |

| 150 | 6 | 444 | 318 | 269.7 | 216 | 36.6 | 12-25.4 | 717 | 400 | 120 |

| 200 | 8 | 559 | 381 | 330.2 | 270 | 41.2 | 12-25.4 | 930 | 500 | 212 |

| 250 | 10 | 622 | 444 | 387.4 | 324 | 47.8 | 16-28.5 | 1012 | 550 | 330 |

| 300 | 12 | 711 | 521 | 450.8 | 381 | 50.8 | 16-32 | 1231 | 600 | 472 |

| 350 | 14 | 762 | 584 | 514.4 | 413 | 54 | 20-32 | 1450 | 600 | 715 |

| 400 | 16 | 864 | 648 | 571.5 | 470 | 57.2 | 20-35 | 1645 | 600 | 920 |

| DN | 600Lb 凸面法蘭(RF)?主要尺寸Dimensions

(mm) |

重量 Weight |

||||||||

| mm | in | L | D | D1 | D2 | b | n-φd | H | D0 | |

| 15 | 1/2 | 165 | 95 | 66.5 | 35 | 14.5 | 4-16 | 285 | 100 | 7.8 |

| 20 | 3/4 | 190 | 117 | 82.5 | 43 | 16 | 4-19 | 285 | 125 | 12.5 |

| 25 | 1 | 216 | 124 | 89 | 51 | 17.5 | 4-19 | 313 | 160 | 17.5 |

| 32 | 11/4 | 229 | 133 | 98.5 | 63 | 21 | 4-19 | 328 | 160 | 23.5 |

| 40 | 11/2 | 241 | 156 | 114.3 | 73 | 22.5 | 4-22.5 | 365 | 180 | 38.5 |

| 50 | 2 | 292 | 165 | 127 | 92 | 33 | 8-19 | 444 | 200 | 35 |

| 65 | 21/2 | 330 | 190 | 149.4 | 105 | 36 | 8-22.5 | 483 | 250 | 50 |

| 80 | 3 | 356 | 210 | 168.1 | 127 | 39 | 8-22.5 | 533 | 250 | 60 |

| 100 | 4 | 432 | 273 | 216 | 157 | 45 | 8-25.4 | 622 | 350 | 110 |

| 125 | 5 | 508 | 330 | 266.7 | 186 | 52 | 8-28.5 | 750 | 350 | 200 |

| 150 | 6 | 559 | 356 | 292.1 | 216 | 55 | 12-28.5 | 800 | 450 | 230 |

| 200 | 8 | 660 | 419 | 349.3 | 270 | 63 | 12-32 | 927 | 500 | 410 |

| 250 | 10 | 787 | 508 | 431.8 | 324 | 71 | 16-35 | 1257 | 600 | 625 |

| 300 | 12 | 838 | 559 | 489 | 381 | 74 | 20-35 | 1468 | 680 | 860 |

The post 美標截止閥 appeared first on 上海三維閥門制造有限公司.

]]>The post 直通式截止閥 appeared first on 上海三維閥門制造有限公司.

]]>特點結構

- 與閘閥相比,截止閥的結構較簡單,制造和維修都比較方便;

- 密封面不易磨損、擦傷、密封性能較好,壽命較長;

- 啟閉時閥瓣行程較小,啟閉時間較短。設計與制造標準:

● 設計與制造: GB12233

● 法蘭尺寸: JB/T79 GB9113

● 結構長度: GB12221

● 檢驗與實驗: GB/T13927

| 公稱壓力 PN |

公稱通徑 DN |

主要連接尺寸 | Z43外形尺寸 | |||||||||

| L | D | D1 | D2 | D6 | b | f | f1 | Z-φd | H | D0 | ||

| 1.6MPa | 15 | 130 | 95 | 65 | 45 | – | 14 | 2 | – | 4-14 | 119 | 75 |

| 20 | 150 | 105 | 75 | 55 | – | 14 | 2 | – | 4-14 | 120 | 75 | 75 |

| 25 | 160 | 115 | 85 | 65 | – | 14 | 2 | – | 4-14 | 126 | 75 | 75 |

| 32 | 180 | 135 | 100 | 78 | – | 15 | 2 | – | 4-18 | 160 | 120 | 120 |

| 40 | 200 | 146 | 110 | 85 | – | 16 | 2 | – | 4-18 | 168 | 120 | 120 |

| 50 | 230 | 160 | 125 | 100 | – | 16 | 3 | – | 4-18 | 194 | 160 | 160 |

| 65 | 290 | 180 | 145 | 120 | – | 18 | 3 | – | 4-18 | – | – | – |

| 80 | 310 | 195 | 160 | 135 | – | 20 | 3 | – | 8-18 | – | – | – |

| 100 | 350 | 215 | 180 | 155 | – | 20 | 3 | – | 8-18 | – | – | – |

| 125 | 400 | 245 | 210 | 185 | – | 22 | 3 | – | 8-18 | – | – | – |

| 150 | 480 | 280 | 240 | 210 | – | 24 | 3 | – | 8-23 | – | – | – |

| 2.5MPa | 15 | 130 | 95 | 65 | 45 | – | 16 | 2 | – | 4-14 | 230 | 120 |

| 20 | 150 | 105 | 75 | 55 | – | 16 | 2 | – | 4-14 | 275 | 140 | |

| 25 | 160 | 115 | 85 | 65 | – | 16 | 2 | – | 4-14 | 295 | 160 | |

| 32 | 180 | 135 | 100 | 78 | – | 18 | 2 | – | 4-18 | 335 | 160 | |

| 40 | 200 | 145 | 110 | 85 | – | 18 | 3 | – | 4-18 | 380 | 200 | |

| 50 | 230 | 160 | 125 | 100 | – | 20 | 3 | – | 4-18 | 398 | 240 | |

| 65 | 290 | 180 | 145 | 120 | – | 22 | 3 | – | 8-18 | 433 | 280 | |

| 80 | 310 | 195 | 160 | 135 | – | 22 | 3 | – | 8-18 | 468 | 320 | |

| 100 | 350 | 230 | 190 | 160 | – | 24 | 3 | – | 8-23 | 520 | 360 | |

| 125 | 400 | 270 | 220 | 188 | – | 28 | 3 | – | 8-25 | 556 | 400 | |

| 150 | 480 | 300 | 250 | 218 | – | 30 | 3 | – | 8-25 | 674 | 400 | |

| 200 | 600 | 360 | 310 | 278 | – | 34 | 3 | – | 12-25 | 806 | 450 | |

| 250 | 650 | 425 | 370 | 332 | – | 36 | 3 | – | 12-30 | 880 | 550 | |

| 300 | 750 | 485 | 430 | 390 | – | 40 | 4 | – | 16-34 | 995 | 800 | |

| 4.0MPa | 15 | 130 | 95 | 65 | 45 | 40 | 16 | 2 | 4 | 4-14 | 230 | 120 |

| 20 | 150 | 105 | 75 | 55 | 51 | 16 | 2 | 4 | 4-14 | 275 | 140 | |

| 25 | 160 | 115 | 85 | 65 | 58 | 16 | 2 | 4 | 4-14 | 295 | 160 | |

| 32 | 180 | 135 | 100 | 78 | 66 | 18 | 3 | 4 | 4-18 | 308 | 160 | |

| 40 | 200 | 145 | 110 | 85 | 76 | 18 | 3 | 4 | 4-18 | 354 | 200 | |

| 50 | 230 | 160 | 125 | 100 | 88 | 20 | 3 | 4 | 4-18 | 380 | 240 | |

| 65 | 290 | 180 | 145 | 120 | 110 | 22 | 3 | 4 | 8-18 | 420 | 280 | |

| 80 | 310 | 195 | 160 | 135 | 121 | 22 | 3 | 4 | 8-18 | 462 | 320 | |

| 100 | 350 | 230 | 190 | 160 | 150 | 24 | 3 | 4.5 | 8-23 | 506 | 360 | |

| 125 | 400 | 270 | 220 | 188 | 176 | 28 | 3 | 4.5 | 8-25 | 556 | 400 | |

| 150 | 480 | 300 | 250 | 218 | 204 | 30 | 3 | 4.5 | 8-25 | 692 | 400 | |

| 200 | 600 | 375 | 320 | 282 | 260 | 38 | 3 | 4.5 | 12-30 | 806 | 450 | |

| 6.4MPa | 15 | 170 | 105 | 75 | 55 | 41 | 18 | 2 | 4 | 4-18 | 210 | 140 |

| 20 | 190 | 125 | 90 | 68 | 51 | 20 | 2 | 4 | 4-18 | 248 | 160 | |

| 25 | 210 | 135 | 100 | 78 | 58 | 22 | 2 | 4 | 4-18 | 275 | 180 | |

| 32 | 230 | 150 | 110 | 82 | 66 | 24 | 3 | 4 | 4-23 | 355 | 200 | |

| 40 | 260 | 165 | 125 | 95 | 76 | 24 | 3 | 4 | 4-23 | 395 | 240 | |

| 50 | 300 | 175 | 135 | 105 | 88 | 26 | 3 | 4 | 4-23 | 450 | 280 | |

| 65 | 340 | 200 | 160 | 130 | 110 | 28 | 3 | 4 | 8-23 | 494 | 320 | |

| 80 | 380 | 210 | 170 | 140 | 121 | 30 | 3 | 4 | 8-23 | 531 | 360 | |

| 100 | 430 | 250 | 200 | 168 | 150 | 32 | 3 | 4.5 | 8-25 | 580 | 400 | |

| 150 | 550 | 340 | 280 | 240 | 204 | 38 | 3 | 4.5 | 8-34 | 710 | 450 | |

The post 直通式截止閥 appeared first on 上海三維閥門制造有限公司.

]]>The post 鍛鋼法蘭截止閥 appeared first on 上海三維閥門制造有限公司.

]]>城建、化工、冶金、石油、制藥、食品、環保

內螺紋與承插焊截止閥標準材質細表

| 序號 | 零件名稱 | CStoASTM | AStoASTM | SStoASTM | |

| A105 | F22 | F304(L) | F316(L) | ||

| 1 | 閥體 | A105 | A182F22 | A182F304(L) | A182F316(L) |

| 2 | 閥瓣 | A276420 | A276304 | A276304(L) | A276316(L) |

| 3 | 閥桿 | A182F6 | A182F304 | A182F304(L) | A182F316(L) |

| 4 | 墊片 | 316夾柔性石墨 | 316夾PTFE | ||

| 5 | 閥蓋 | A105 | A276f304 | A276F304(L) | A276F316(L) |

| 6 | 螺栓 | A193B7 | A193B16 | A193B8 | A193B8M |

| 7 | 銷釘 | A276420 | A276 304 | ||

| 8 | 填料壓套 | A276410 | A182F304(L) | A182F316(L) | |

| 9 | 活節螺栓 | A193B7 | A193B16 | A193B8 | A193B8M |

| 10 | 填料壓板 | A216WCB | A351CF8 | ||

| 11 | 螺母 | A1942H | A1944 | A1948 | A1948M |

| 12 | 閥桿螺母 | A276410 | |||

| 13 | 鎖緊螺母 | A1942H | A1944 | A1948 | A1948M |

| 14 | 銘牌 | SS | |||

| 15 | 手輪 | A197 | |||

| 16 | 填料 | 柔性石墨 | PTFE | ||

| 適用介質 | 水、蒸汽、油品等 | 水、蒸汽、油品等 | 硝酸、醋酸等 | ||

| 適用溫度 | —29℃~425℃ | —29℃~550℃ | —29℃~200℃ | ||

注意:客戶需求的其他材質也可采用。密封面料配對由客戶指定內件代號決定。

CS=碳鋼;AS=合金鋼;SS=不銹鋼;

內螺紋與承插焊截止閥

尺寸(mm)和重量(kg)

| NPS | 縮徑 | 3/8″ | 1/2″ | 3/4″ | 1″ | 11/4″ | 11/2″ | 2″ | |

| 全徑 | 3/8″ | 1/2″ | 3/4″ | 1″ | 11/4″ | 11/2″ | 2″ | ||

| L | 79 | 79 | 92 | 111 | 120 | 152 | 172 | 200 | |

| H(開) | 166 | 166 | 171 | 207 | 240 | 258 | 330 | 355 | |

| W | 100 | 100 | 100 | 125 | 160 | 160 | 180 | 200 | |

| 重量 | 螺栓式 | 1.9 | 1.9 | 2.1 | 3.5 | 6.0 | 7.5 | 11.4 | 14.6 |

| 焊接式 | 1.7 | 1.7 | 1.9 | 3.3 | 5.2 | 6.8 | 10.6 | 13.8 | |

The post 鍛鋼法蘭截止閥 appeared first on 上海三維閥門制造有限公司.

]]>The post 低溫截止閥 appeared first on 上海三維閥門制造有限公司.

]]>執行標準

設計與制造:JB/T7749-95

結構長度:GB/T12221-89

連接端:GB/T9113-2000,HG20592-97,SH3406-96GB/T12224-89

檢驗與試驗:JB/T7749-95

性能參數

| 型號 | DJ41Y-16 | DJ41Y-16P | DJ41Y-25 | DJ41Y-25P | DJ41Y-40 | DJ41Y-40P | |

| 工作壓力(MPa) | 1.6 | 2.5 | 4.0 | ||||

| 適用溫度(℃) | -45 | -101 | -196 | ||||

| 適用介質 | 液化天然氣、乙烯、丙烯等低溫介質 | ||||||

| 材料 | 閥體、閥蓋 | LCB | LC3 | LCB | LC3 | LCB | LC3 |

| 閥瓣、閥座 | 鉻鎳鋼+鈷鉻鎢 | ||||||

| 閥桿 | 鉻鎳鋼 | ||||||

The post 低溫截止閥 appeared first on 上海三維閥門制造有限公司.

]]>The post 波紋管截止閥 appeared first on 上海三維閥門制造有限公司.

]]>廣泛應用于:石油化工、化纖紡織、塑料造紙、電力鋼鐵、印染橡膠、食品等工業。

結構特點

- 產品結構合理、密封可靠,雙重堅固耐用的波紋管密封設計(波紋管+填料),保證閥桿的零泄漏。沒有流體損失,提高工廠設備安全。并符合國際密封標準。

- 密封面堆焊Co基硬質合金、耐磨、耐腐、抗摩擦性能好、使用壽命長

- 閥桿調質及表面氮化處理,有良好的抗腐和抗摩擦性能;閥桿升降位置指示,更直觀。

技術規范

| 驅動方式 | 手動 |

| 電動 | |

| 設計標準 | DIN3356 |

| 結構長度 | DIN3202 |

| 連接法蘭 | DIN2543-2545 |

| 試驗和檢驗 | DIN3230 |

產品性能規范

| 公稱壓力(MPa) | 殼體試驗壓力(MPa) | 密封試驗壓力(MPa) | 適用溫度(℃) |

| 1.6 | 2.4 | 1.76 | ≤350℃ |

| 2.5 | 3.75 | 2.75 | |

| 4.0 | 6.0 | 4.4 | |

| 6.4 | 9.6 | 7.04 |

注:系列閥門連接法蘭可根據用戶要求設計制造

零件材料

| 零件名稱 | 閥體 | 閥蓋 | 閥桿 | 閥瓣 | 密封面 | 填料 |

| WCB | WCB | WCB | 13Cr | 2Cr13 | 2Cr13 | 柔性石墨 |

| STL | ||||||

| 304 | CF8 | CF8 | 304 | 304 | 304 | 柔性石墨 |

| STL | PTFE | |||||

| 316 | CF8M | CF8M | 316 | 316 | 316 | 柔性石墨 |

| STL | PTFE | |||||

| 304L | CF3 | CF3 | 316 | 304L | 304L | 柔性石墨 |

| STL | PTFE | |||||

| 316L | CF3M | CF3M | 316 | 316L | 316L | 柔性石墨 |

| STL | PTFE |

規格尺寸及重量

| 型號 | DWJ41-16 | ||||||||||||||

| 壓力等級 | PN16 | ||||||||||||||

| 口徑 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 |

| H | 195 | 200 | 220 | 225 | 235 | 250 | 260 | 265 | 370 | 400 | 515 | 550 | 600 | 630 | 680 |

| Do | 130 | 130 | 130 | 130 | 150 | 150 | 180 | 180 | 200 | 200 | 400 | 450 | 450 | 500 | 500 |

| 重量(Kg) | 4 | 4.5 | 5 | 7 | 9 | 12.5 | 18 | 23 | 41 | 54 | 90 | 160 | 260 | 410 | 610 |

| 型號 | DWJ41-25 | ||||||||||||||

| 壓力等級 | PN25 | ||||||||||||||

| 口徑 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 |

| H | 195 | 200 | 220 | 225 | 235 | 250 | 260 | 265 | 370 | 400 | 515 | 550 | 600 | 630 | 680 |

| Do | 130 | 130 | 130 | 130 | 150 | 150 | 180 | 180 | 200 | 200 | 400 | 450 | 450 | 500 | 450 |

| 重量(Kg) | 4 | 4.5 | 5 | 7 | 9.5 | 13 | 19 | 24 | 43 | 57 | 95 | 168 | 300 | 510 | 680 |

| 型號 | DWJ41-40 | ||||||||||||||

| 壓力等級 | PN40 | ||||||||||||||

| 口徑 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 |

| H | 195 | 200 | 220 | 225 | 235 | 250 | 260 | 265 | 370 | 400 | 515 | 550 | 600 | 630 | 680 |

| Do | 130 | 130 | 130 | 130 | 150 | 150 | 180 | 180 | 200 | 200 | 400 | 450 | 450 | 500 | 500 |

| 重量(Kg) | 4 | 4.5 | 5 | 8 | 10 | 13.5 | 20 | 25 | 45 | 60 | 98 | 171 | 340 | 580 | 780 |

The post 波紋管截止閥 appeared first on 上海三維閥門制造有限公司.

]]>